Gib and Slide Assemblies

Gib and slide assemblies are critical components for precise linear guidance in dies, molds, and heavy-duty machinery. By reducing friction and maintaining alignment under load, they ensure smooth and reliable motion in complex tooling applications.

SelfLube’s assemblies are pre-engineered and ready to install, saving toolmakers significant time during build. With aluminum bronze wear surfaces, available with or without self-lubricating graphite, these assemblies are built to handle demanding production environments while reducing maintenance needs.

Featured Gib & Slide Assembly Options:

Mold Gib Assemblies

PA Style Gib Assemblies

Standard Gib Assemblies

MA Gib Assemblies (tight tolerance, no doweling required)

Square Gib Assemblies

Quick Slides (includes base, slide, angle pin, wedge, and slide lock)

Trunnion Lifter Slides (inch, angled, metric, and adjustable options)

Why Choose SelfLube Gib & Slide Assemblies?

Pre-engineered for fast installation and reduced build time

Aluminum bronze wear surfaces for long-lasting durability

Optional graphite inserts for smoother, low-maintenance operation

Broad range of standard and custom configurations

Industries We Serve:

Metal stamping

Plastic injection molding

Special machine building

Heavy-duty tooling operations

Request a quote today or contact us for more information!

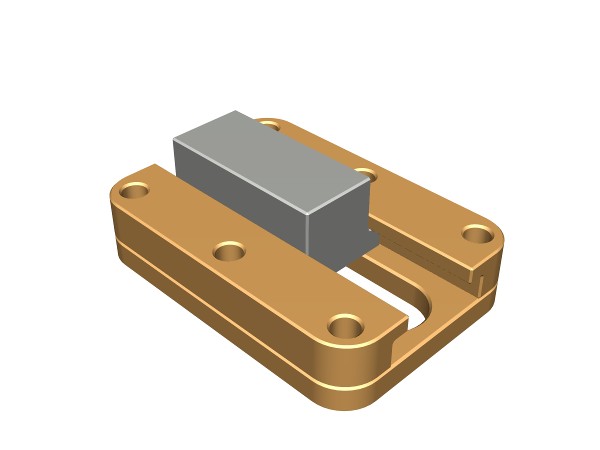

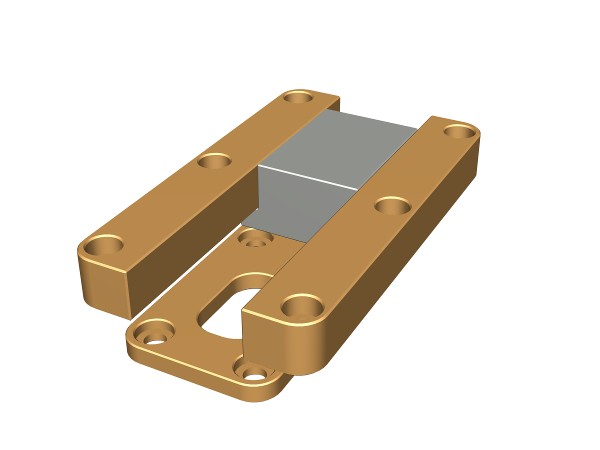

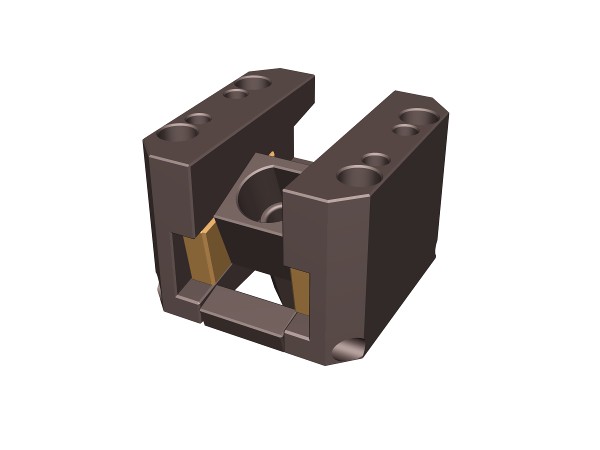

Mold Gib Assemblies

Mold Gib Assemblies

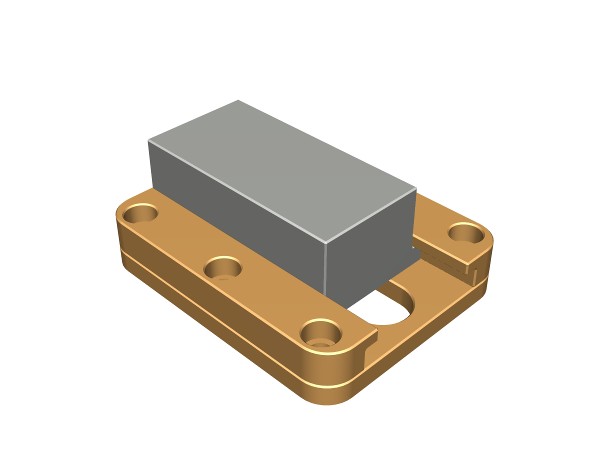

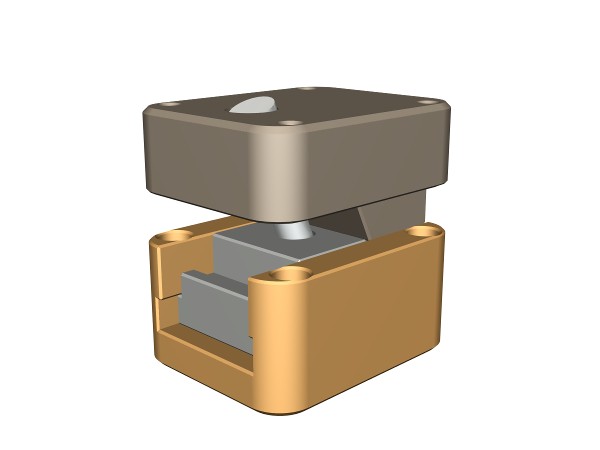

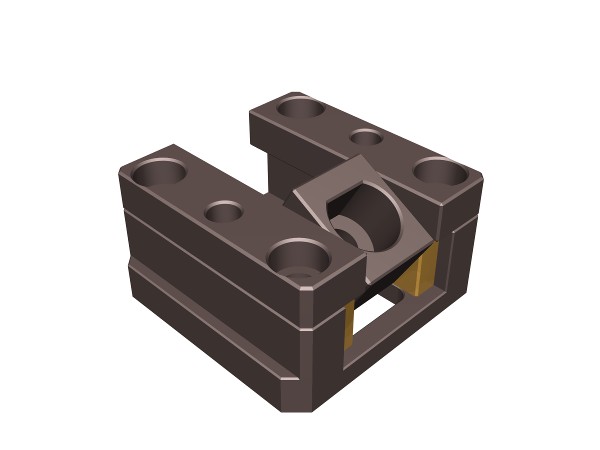

PA Style Gib Assemblies

PA Style Gib Assemblies

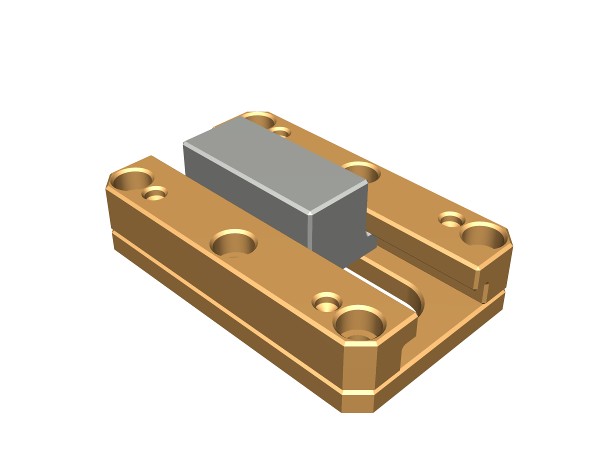

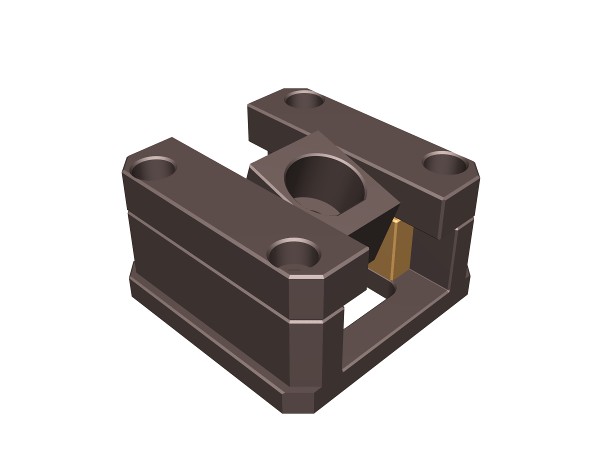

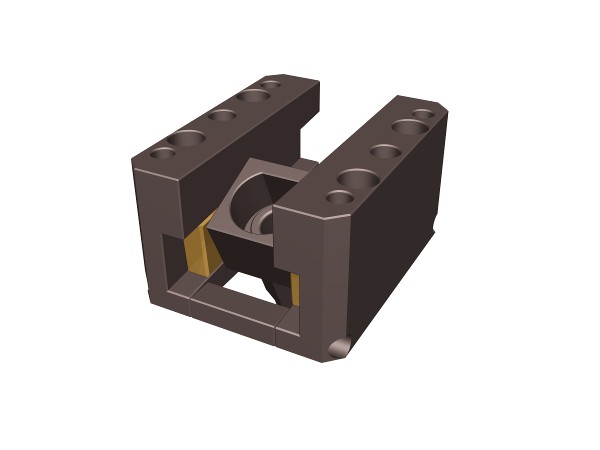

Standard Gib Assemblies

Standard Gib Assemblies

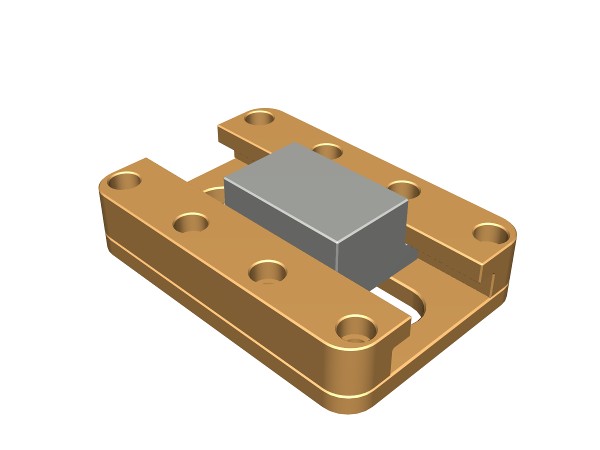

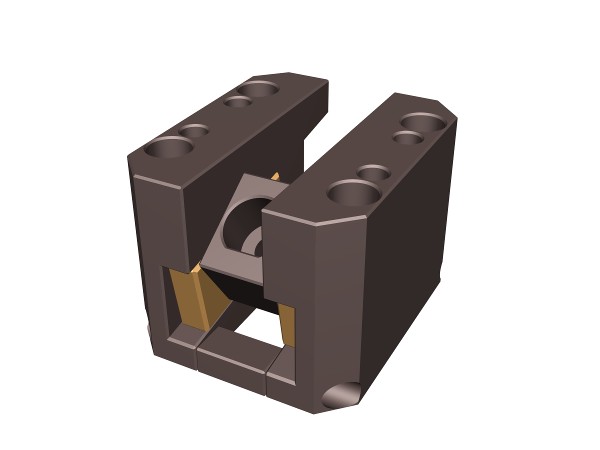

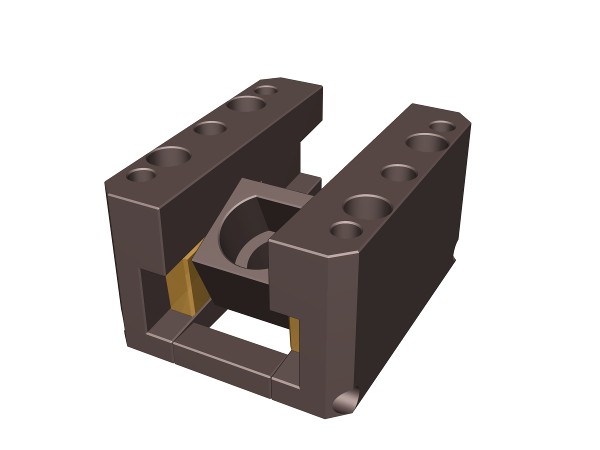

MA Gib Assemblies

MA Gib Assemblies

Square Gib Assemblies

Square Gib Assemblies

Quick Slides

Quick Slides

Trunnion Lifter Slides - Inch

Trunnion Lifter Slides - Inch

Trunnion Lifter Slides - Angled

Trunnion Lifter Slides - Angled

Trunnion Lifter Slides - Angled and Adj.

Trunnion Lifter Slides - Angled and Adj.

Trunnion Lifter Slides - Metric

Trunnion Lifter Slides - Metric

Trunnion Lifter Slides - Metric Angled

Trunnion Lifter Slides - Metric Angled

Trunnion Lifter Slides - Metric Angled and Adj.

Trunnion Lifter Slides - Metric Angled and Adj.