The Leading U.S. Manufacturer of Precision Mold and Die Components

We make tough reliable components that guide the moving parts in complex tools, special machines and outdoor equipment. Our products include wear plates, gibs, slides, guide pins, guide posts, bronze bushings, and graphite plugged bushings. We offer 10,000 standard part numbers. We also make custom parts. Our plant is located in West Michigan so there is no long overseas supply chain to contend with. We’re known for our excellent customer service. When you call, we don't waste your time. A real person answers the phone. We are also a Continuous Improvement Company. Our customers benefit from over 25 years of improvements related to Quality and Cost Containment. This has given us an earned reputation for being an exceptional supplier.

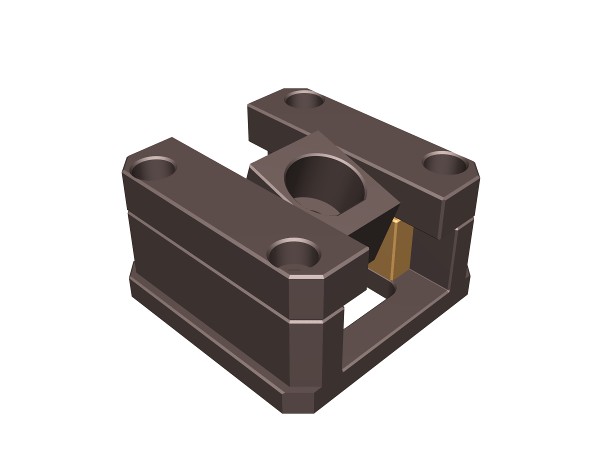

Trunnion Lifter Slides - Inch

Trunnion Lifter Slides - Inch

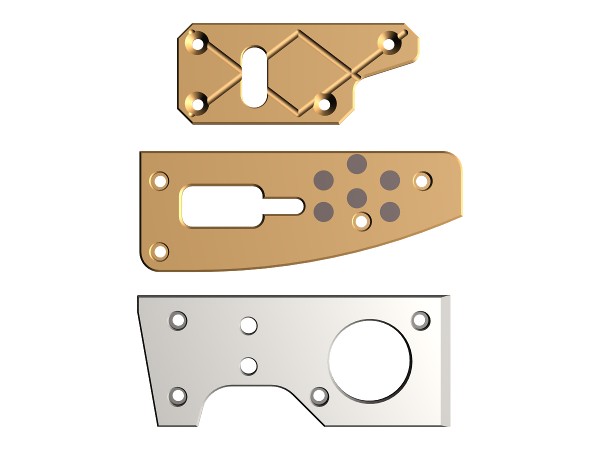

Custom Wear Strips

Custom Wear Strips